PCB circuit board cooling skills

From week Electronic Engineering News: The heat generated by electronic equipment during operation causes the internal temperature of the equipment to rise rapidly. If the heat is not dissipated in time, the equipment will continue to heat up, the device will fail due to overheating, and the reliability of electronic equipment will decline. Therefore, it is very important to heat dissipate the circuit board.

First, the analysis of printed circuit board temperature rise factors

The direct cause of the temperature rise of the printed board is due to the presence of circuit power consumption devices, electronic devices have power consumption to varying degrees, and the intensity of heat varies with the power consumption.

Two phenomena of temperature rise in printed board:

(1) Local temperature rise or large area temperature rise;

(2) Short-term temperature rise or long-term temperature rise.

When analyzing PCB thermal power consumption, generally from the following aspects.

1. Electrical power consumption

(1) Analysis of power consumption per unit area;

(2) Analyze the distribution of power consumption on the PCB circuit board.

2. Structure of printed board

(1) The size of the printed board;

(2) The material of the printed board.

3. Installation method of printed board

(1) Installation method (such as vertical installation, horizontal installation);

(2) The sealing condition and the distance from the casing.

4. Heat radiation

(1) Emissivity of printed board surface;

(2) The temperature difference between the printed board and the adjacent surface and their absolute temperature;

5. Heat conduction

(1) Install the radiator;

(2) Conduction of other installation structural parts.

6. Thermal convection

(1) Natural convection;

(2) Forced cooling convection.

The analysis of the above factors from the PCB is an effective way to solve the temperature rise of the printed board. These factors are often interrelated and dependent on a product and system. Most factors should be analyzed according to the actual situation, only for a specific Only actual conditions can calculate or estimate the temperature rise and power consumption parameters correctly.

Second, the circuit board cooling method

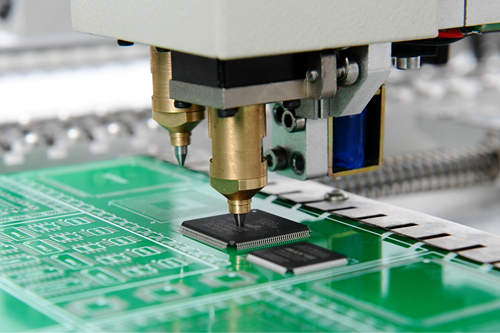

1. High heat-generating device plus heat sink and heat-conducting plate

When a few devices in the PCB generate a lot of heat (less than 3), a heat sink or heat pipe can be added to the heat-generating device. When the temperature cannot be lowered, a heat sink with a fan can be used to enhance heat dissipation effect. When there are more heating devices (more than 3), a large heat sink (board) can be used. It is a special radiator customized according to the position and height of the heating device on the PCB board or in a large flat radiator Cut out the height of different components. Fasten the heat dissipation cover to the component surface, and contact each component to dissipate heat. However, due to the poor consistency of the components during assembly and welding, the heat dissipation effect is not good. Usually a soft thermal phase change thermal pad is added on the component surface to improve the heat dissipation effect.

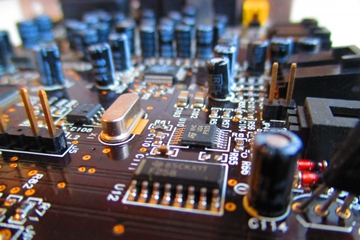

2. Heat dissipation through the PCB board itself

Currently widely used PCB sheet is copper-clad / epoxy glass cloth substrate or phenolic resin glass cloth substrate, and there are a few paper-based copper-clad sheets used. Although these substrates have excellent electrical performance and processing performance, they have poor heat dissipation. As a heat dissipation route for high heat-generating components, the PCB itself can hardly be expected to conduct heat from the resin of the PCB, but to dissipate heat from the surface of the component to the surrounding air. However, as electronic products have entered the era of miniaturization of components, high-density installation, and high-heat assembly, it is not enough to rely on the surface of components with very small surface area to dissipate heat. At the same time, due to the heavy use of surface-mounted components such as QFP and BGA, the heat generated by the components is transferred to the PCB board in large quantities. Therefore, the best way to solve the heat dissipation is to improve the heat dissipation capacity of the PCB itself in direct contact with the heating element. Conduct or emit.

Comparison Between PCB Prototyping Service and Standard PCB Fabrication Service

Comparison Between PCB Prototyping Service and Standard PCB Fabrication Service

The Domestic Capital Era of China Printed Circuit Boards

The Domestic Capital Era of China Printed Circuit Boards

How to distinguish the quality of PCB circuit board?

How to distinguish the quality of PCB circuit board?